One last item...

Are you a designer, engineer or inventor with an idea or drawing but you don't know where to turn next?

Give us a call or drop us an email and let us assist you in turning your vision into a reality.

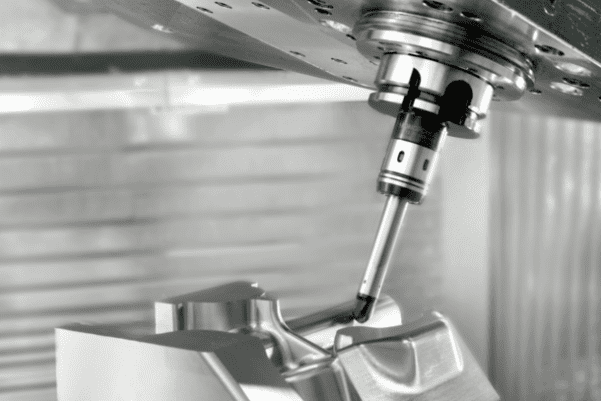

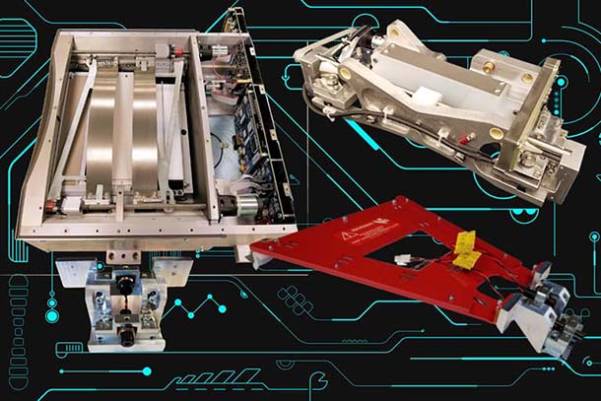

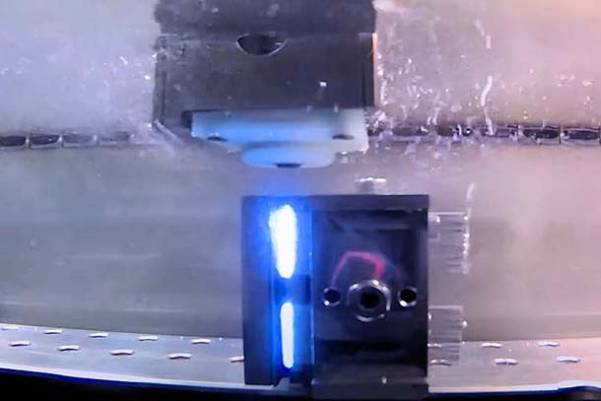

With over 50 years of experience in CNC Machining and Electro-Mechanical Assembly, we have developed and perfected a system of processes and procedures to ensure the highest quality deliverables –at affordable rates– that will meet your budget.

No matter the size of the project, or its complexity, we guarantee your satisfaction. Our fully trained technicians and management staff focus not just on the big picture, but the smallest details. Which, in the end, is what differentiates between an adequate product and an outstanding one.

The outcome?

The peace of mind knowing that your product is in good hands and that we will never sacrifice quality…for any reason!

In this uncertain environment we find ourselves in, you have many old and new challenges you must deal with every day. Rising prices, scarcity of raw material and electronics, extended lead times, and the challenges of finding and retaining high quality personnel. We understand your concerns, which is why Precise Tool & Die maintains a wide and diverse global supply chain with a substantial level of redundancies. We always prefer to utilize our local and regional suppliers whenever possible, but the needs of our customers will always dictate the most productive and cost efficient methods we employ to ensure the highest level of satisfaction.

Your benefit?

No surprises and one less thing to worry about. We take our promises seriously and you can be assured that your product will be delivered when needed and at the lowest cost possible while ensuring the quality you demand.

You’ve heard it all before…

“We’re the best!”

“Our competitors can’t compare!”

“We can do no wrong!”

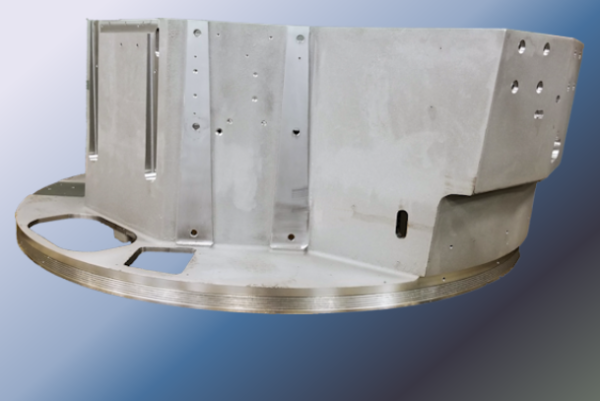

We won’t waste your valuable time. The old saying goes, “A picture is worth a thousand words.” With that in mind, take a look at a small sample of the quality products we have produced for our customers all over the world…

Hours:

Monday-Friday 8am-5pm

Phone:

(440) 951-9173

Email: