CAPABILITIES

CNC MILLING

• Five milling centers •

• Work capacity up to 43″ x 22″ x 20″ •

• 15,000 maximum spindle RPM’s •

• Full 4-Axis capabilities •

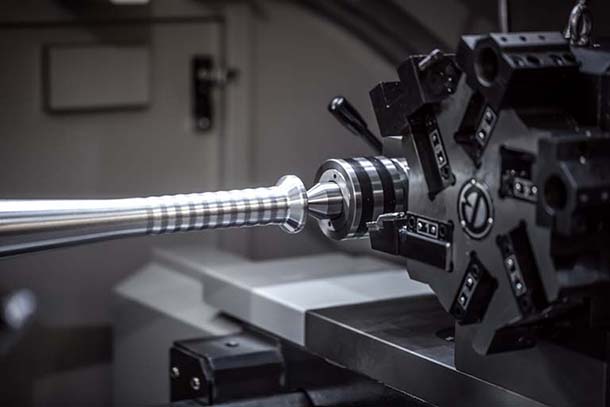

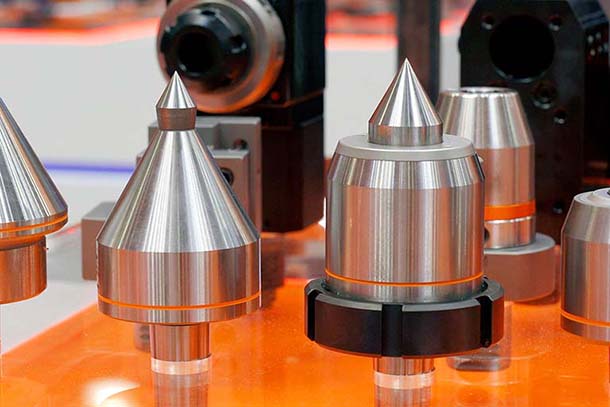

CNC TURNING

• Three turning centers •

• Work capacity up to Ø 26″ x 72″ long •

• 15,000 maximum spindle RPM’s •

• Live tooling capabilities •

CNC HORIZONTAL BORING MILL

• Two boring mill centers •

• Work capacity up to 118″ x 80″ x 54″ •

• 15,000 maximum spindle RPM’s •

• Full 4-Axis capabilities •

LARGE CAPACITY HORIZ. MILLING

• Two twin-pallets machine centers •

• Work capacity up to 60″ x 60″ x 65″ •

• 12,000 maximum spindle RPM’s •

• Renishaw probing capabilities •

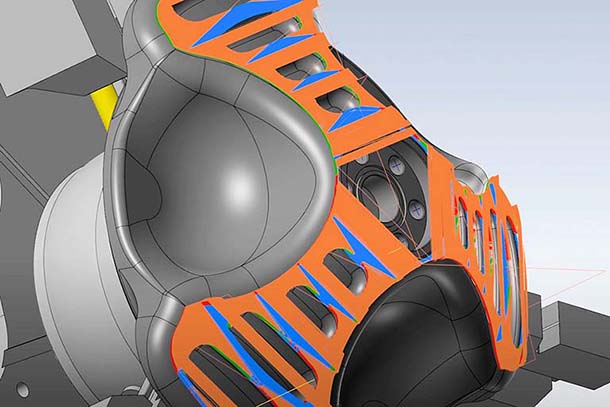

3D SURFACE MACHINING

• Five milling centers •

• Work capacity up to 43″ x 22″ x 20″ •

• 15,000 maximum spindle RPM’s •

• Full 4-Axis capabilities •

CONVENTIONAL MACHINING

• Conventional Milling & Lathe •

• Conventional Tool & Die Making •

• Conventional Jigs, Fixtures & Prototypes •

• Conventional Small Quantity Machining •

HIGH SPEED CNC MODULAR MACHINING

• Two horizontal machining centers •

• Work capacity up to 24″ x 24″ x 39″ on 24 Pallets •

• 15,000 maximum spindle RPM’s •

• Full 4-Axis capabilities •

FABRICATION

• 60″ x 96″ Laser Cutting Capacity •

• Eight Axis CNC Press Break •

• 50 Ton Strength •

• Full Metal Forming Capabilities •

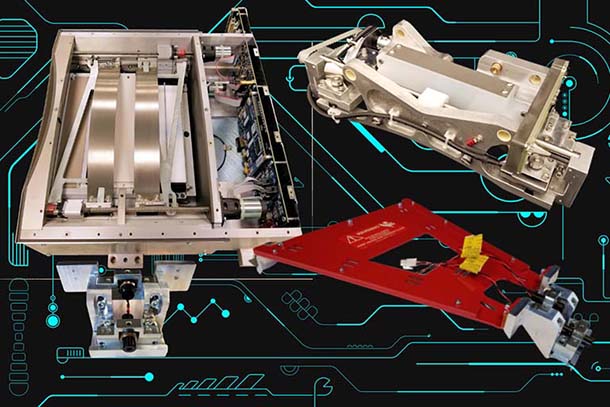

ASSEMBLY

• Manufacturing of all assembly parts •

• Full assembly capabilities •

• Service & Repair •

• Customized Packaging & Documentation •

ELECTRO-MECHANICAL ASSEMBLY

• Discrete Testing & Calibration •

• Full assembly capabilities •

• FDA Accredited Service & Repair •

• Discrete Soldering & Electronic Integration •

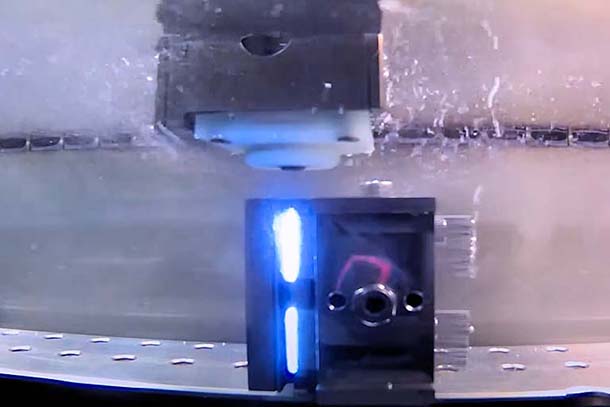

WIRE EDM

• Work Capacity up to 39.4″ x 31.5″ x 15.8″ •

• Ø 0.016″ wire •

• U & V Axis of +/- 3.0° •

• Extra Large Tank Size •

SECONDARY OPERATIONS

• Surface Hardening, Annealing & Tempering •

• Painting & Powder Coating •

• Black Oxide, MedCoat, Electroplating, etc. •

• Chrome, Tin, Zinc, Nickel, etc. •

PRODUCT DEVELOPMENT SUPPORT

• Autodesk AutoCad • Autodesk Inventor •

• AutoCad Mechanical • AutoCad Electrical •

• GibbsCAM • MasterCAM •

• Adobe After Effects • Adobe Illustrator •

• Full Motion Graphics Capabilities •

QUALITY ASSURANCE

• State-of-the-art Hexagon CMM •

• Vast array of fully calibrated gages & Pins

• Customer Tailored Inspection Process •

• Metric & Imperial Measuring Capabilities •

• ISO 9001:2015 QMS Certified •